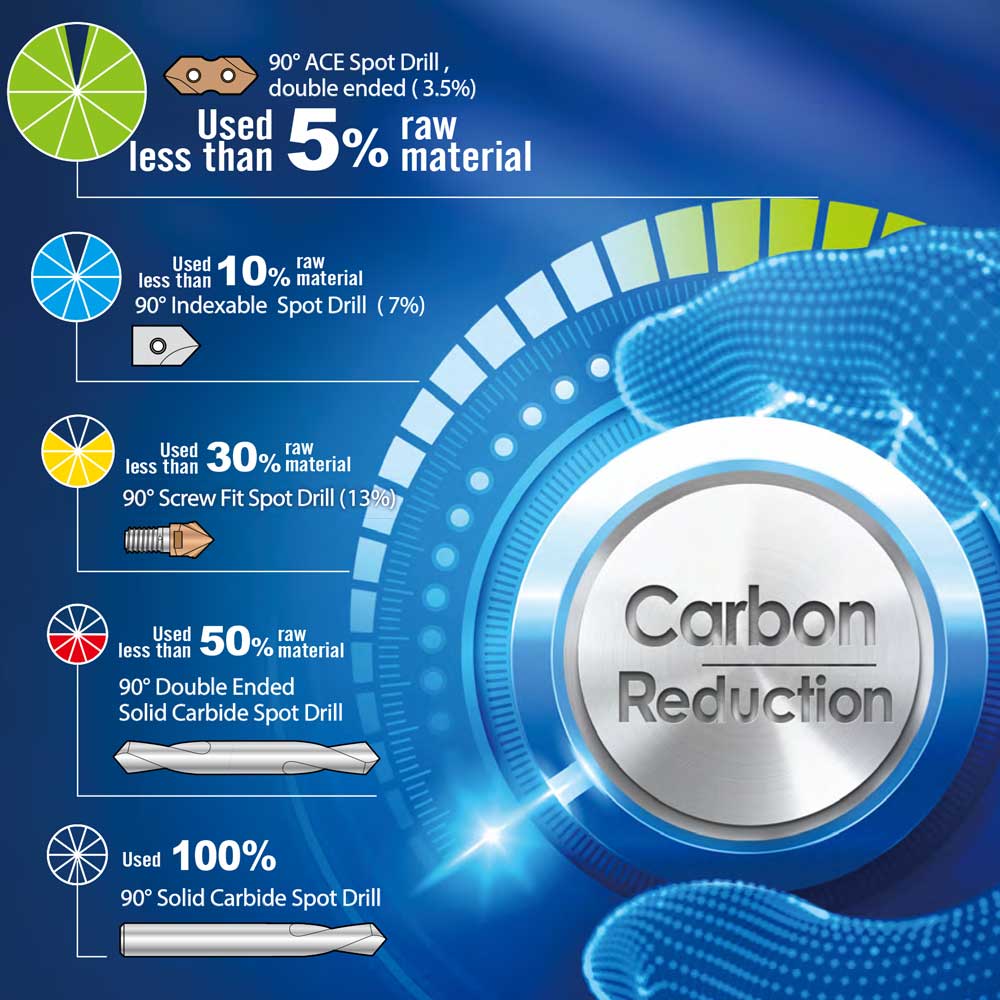

With carbon neutrality becoming a global priority, Nine8. has integrated sustainable practices into their cutting tool production. Through the MCC (Minimum Consumable Cutting) Indicator, Nine9 designs indexable inserts that use less than 5% of the carbide material compared to solid carbide tools, reducing waste and carbon emissions. Their approach, rooted in responsible consumption and production (aligned with the UN’s Sustainable Development Goals), reflects their commitment to efficiency, eco-friendly manufacturing, and innovation in cutting tools.

The products of indexable insert saves a lot of unnecessary material waste and allows resources to be more focused on providing more value to customers. For example, the same raw materials can only be used once in general solid carbide tool manufacturers, Nine9 uses the innovation of the design structure of indexable insert to make the same weight of raw materials can be used nearly 20 times, which greatly reduces the required raw materials consumption, reduces carbon emissions, and at the same time delivers performance that exceeds the expectations of customers.

The policy of carbon neutrality will have a significant impact on the carbon tariffs on all manufacturing industry and import- export commodities in the near future.

"To reduce carbon, first reduce the amount". We have embraced the concept of MCC (Minimum Consumable Cutting) and set up an indicator to ourselves. Each Nine9 insert only takes <5% carbide raw material compared to a whole solid carbide tool and still can reach same performance.